汽车配件入库出库流程(江鸿助手(九)——Flexsim生产线产品入库与出库仿真)

Posted

篇首语:树怕烂根,人怕无志。本文由小常识网(cha138.com)小编为大家整理,主要介绍了汽车配件入库出库流程(江鸿助手(九)——Flexsim生产线产品入库与出库仿真)相关的知识,希望对你有一定的参考价值。

汽车配件入库出库流程(江鸿助手(九)——Flexsim生产线产品入库与出库仿真)

江鸿助手(九)——Flexsim生产线产品的入库与出库仿真

分享兴趣,传播快乐,增长见闻,留下美好。亲爱的您,这里是Learningyard新学苑,今天,小编给大家带来:江鸿助手(九)——Flexsim生产线产品的入库与出库仿真。

Share interest, spread happiness, increase knowledge, leave good. Dear you, this is Learningyard New Academy. Today, Xiaobian brings to you: Jianghong Assistant (IX) -- warehousing and warehousing simulation of Flexsim production line products.

1.问题描述

本次实验可以看作是模拟仓库。首先是两种不同的产品按照正态分布到达,一种是红色,一种是紫色;货物到了之后先到暂存区,随后经过操作员搬运到处理器上并预置产品,经处理器处理后通过传送带和堆垛机存放在货架上,最小停留时间服从指数分布。在堆垛机堆满后会通过传送带运出。

1. Problem description

This experiment can be seen as a simulated warehouse. First, two different products arrive according to a normal distribution, one is red, one is purple; Upon arrival, the goods first go to the temporary storage area, and then are transported to the processor by the operator and preset products. After being processed by the processor, the goods are stored on the shelves by the conveyor belt and the stacker, and the minimum residence time follows the exponential distribution. After the stacker is full, it is carried out on a conveyor belt.

2.模型总体布局

2. Overall layout of the model

3.实体参数设置

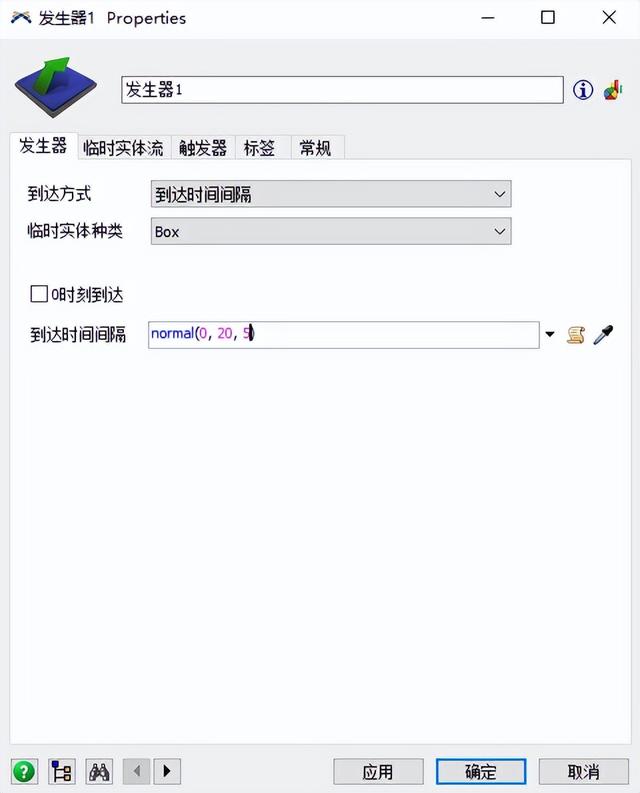

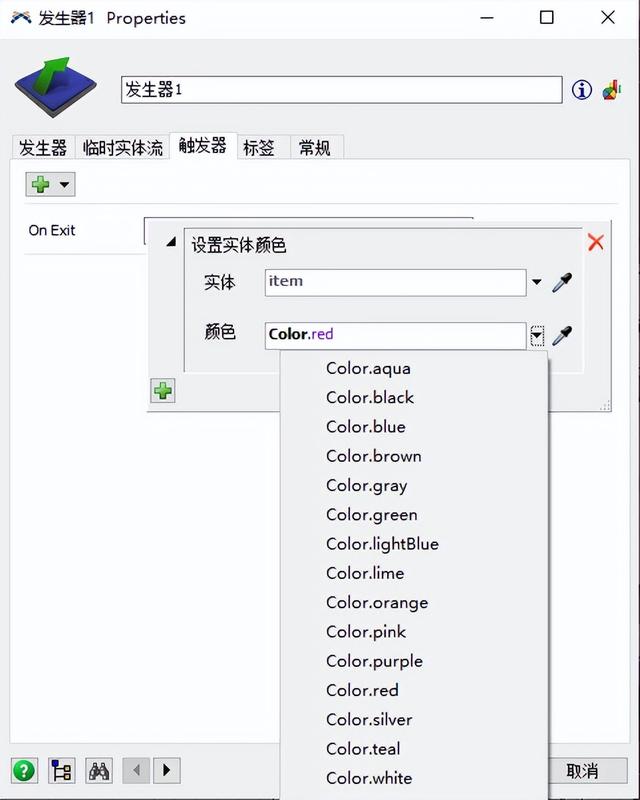

首先设置生成器的参数,两个生成器都按照正态分布(均值为0,方差20)生成产品,两个生成器一个生成红色的产品,一个生成紫色的产品:

3. Set entity parameters

First, set the parameters of the generator. Both generators generate products according to the normal distribution (mean 0, variance 20). One of the two generators generates a red product and the other one generates a purple product:

随后对暂存区进行设置,在Flow选项卡下选择“使用运输工具”;

接着对处理器进行操作:预置时间设置为2分钟,处理时间设置为6分钟,并选择“使用操作员”;

随后,对传送带进行设置:传送带的传送速度设置为2m/s;

Then set up the staging area by selecting "Use Transport" under the Flow TAB:

Then perform operations on the processor: Set the preset time to 2 minutes, the processing time to 6 minutes, and select "Use Operator" :

Then, the conveyor belt is set: the transmission speed of the conveyor belt is set to 2m/s;

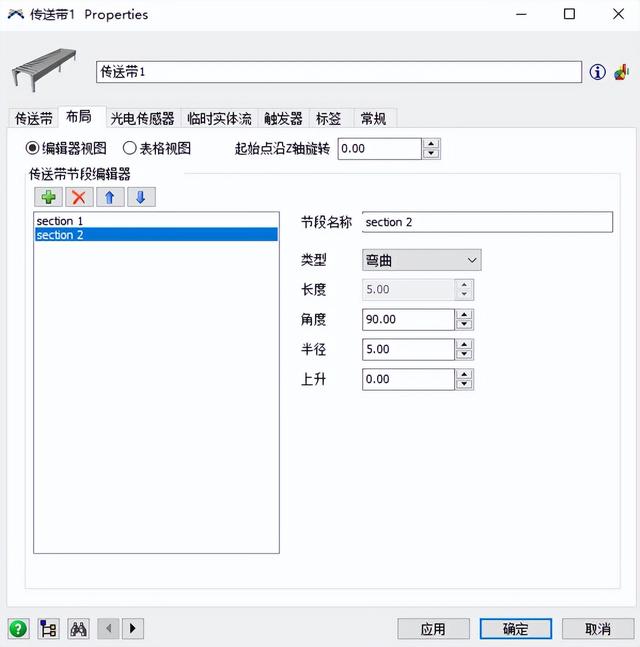

但是,此时的传送带是直的,为了更加贴合实际,我们需要把传送带设置为后半段或前半段是弯曲的,并适当地对整个传送带进行旋转:在传送带的“布局”窗口,点击左上角的加号,把传送带分为两个部分,根据我们的需要,把传送带的第一或第二部分改为“弯曲”,弯曲角度为90度或-90度,随后再对传送带进行适当地旋转即可(有的需要,有的不需要):

However, in this case, the conveyor belt is straight. To be more realistic, we need to make the conveyor belt society curved in the second or first half, and rotate the whole conveyor belt appropriately: In the "Layout" window of the conveyor belt, click the plus sign in the upper left corner to divide the conveyor belt into two parts. According to our needs, change the first or second part of the conveyor belt to "bend" with the bending Angle of 90 degrees or -90 degrees, and then rotate the conveyor belt appropriately (some need, some don't) :

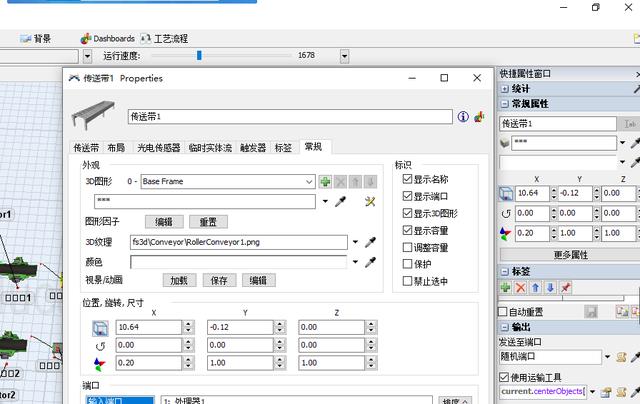

在传送带的“常规”选项卡下或者右边的快捷选项卡下就可以对传送带进行旋转(在x y面下旋转就需要对z轴方向的角度操作):

The conveyor belt can be rotated under the General TAB or the shortcut TAB on the right (rotating under the X and Y planes requires an Angle operation in the Z direction) :

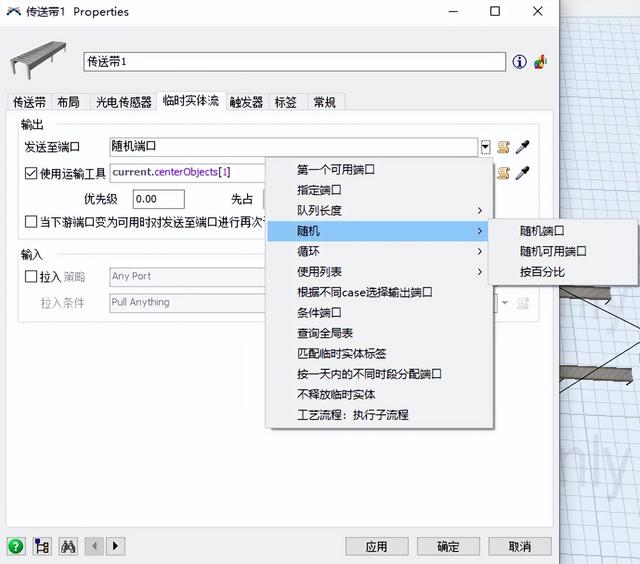

在传送带的Flow窗口下,在“发送至端口”下拉列表选择“随机”,再在“随机”里选择“随机端口”,并选择使用运输工具:

In the Conveyor Flow window, select "Random" from the "Send to Port" drop-down list, then select "Random Port" from "Random", and select Use transport:

最后对货架进行操作,使用堆垛机把货物从传送带上运到货架上:在货架的“临时实体流(Flow)”选项卡下选择“使用运输工具”。

Finally operate the shelves, using the stacker to move goods from the conveyor belt to the shelves: select "Use Transport" under the "Flow" TAB of the shelves.

4.总运行模型图及结果

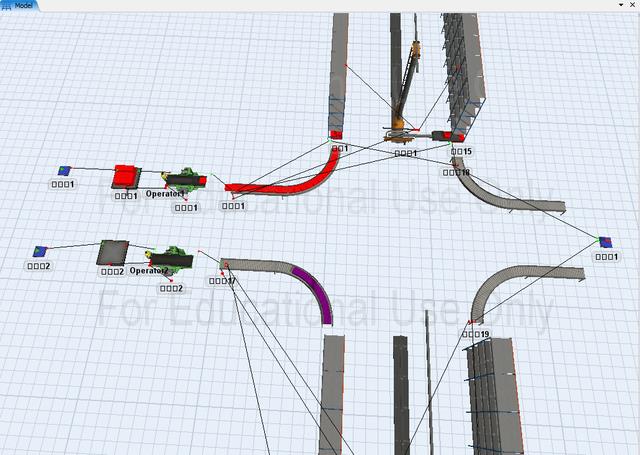

总运行模型图:

4. General operation model diagram and results

Overall operation model diagram:

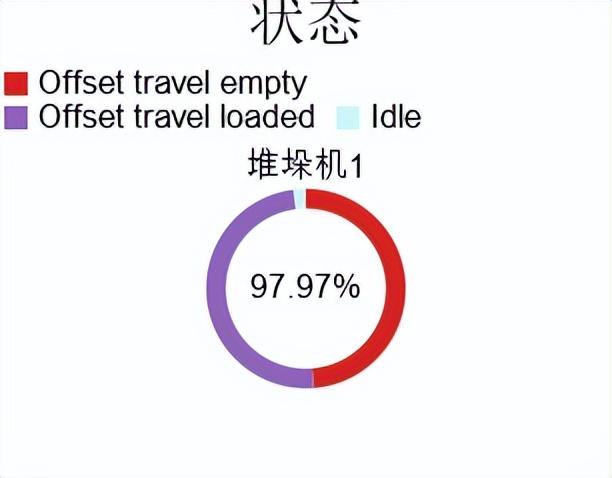

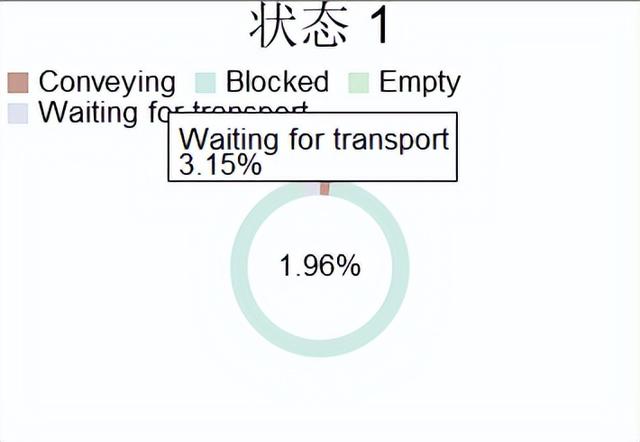

结果:堆垛机的工作状态:几乎每时每刻都在堆垛产品,处于高负荷运转:

Results: The working state of the stacker: almost all the time, the stacker is in high load operation:

第一条传送带的工作状态:大部分时间也都在工作。

How the first conveyor belt works: It works most of the time, too

堆垛机和传送带利用率过高,在现实生产中如果利用率过高会对机器造成不可逆的不利影响,所以要适当降低利用率,可以让货物来得更慢些。

The utilization rate of stacker and conveyor belt is too high. In actual production, if the utilization rate is too high, it will cause irreversible adverse effects on the machine. Therefore, it is necessary to reduce the utilization rate appropriately to make the goods come more slowly.

5.实验心得

在设计产品的入库与出库系统时,既要考虑到产品到达的时间,还要考虑仓库中处理器、传送带和堆垛机的处理速度。在本次仿真中,如果不使用堆垛机,产品经过传送带后就直接放置到货架上,那那么就不会产生拥堵的现象,可见堆垛机对产品的处理速度对产品入库的效率影响很大。因此在设计系统时可以优化产品堆放的方式,既可以对货架优化,如减少货架长度,增加宽度,这样可以一定程度上缩短堆垛机所走路程;或者使用多台堆垛机或者多种堆垛机器,提高产品入库效率。

5.The experiment result

In the design of the product warehousing and warehousing system, we should consider not only the arrival time of the product, but also the processing speed of the processor, conveyor belt and stacker in the warehouse. In this simulation, if the stacker is not used, the product will be directly placed on the shelf after passing through the conveyor belt, so there will be no congestion phenomenon. It can be seen that the processing speed of the product by the stacker has a great impact on the efficiency of product warehousing. Therefore, in the design of the system can optimize the way of product stacking, both can optimize the shelf, such as reducing the shelf length, increase the width, which can shorten the distance of the stacker to a certain extent; Or use multiple stacker or multiple stacker machines to improve the efficiency of product warehousing.

今天的分享就到这里,如果您对今天的文章有独到的见解,欢迎给我们留言,让我们相约明天,祝您今天过得开心快乐!

That's all for today's sharing. If you have unique insights into today's article, please leave us a message and let us meet tomorrow. I wish you a happy and happy life today!

本文由learningyard新学苑原创,如有侵权,请联系我们

翻译来源于有道翻译

图片来源于Flexsim2020截图

相关参考

ERP笔记一:采购部需求单—采购订单-到货单-采购入库单每月1-5日结账,需退出ERP才能结账。二:销售部1是填写销售订单2是根据销售订单,生成销售发货单3根据销售发货单生成销售发票4每月1-5日结账备注:每张单据制单完成保...

客户需求:*经销商自己有一套进销存管理软件,出库单、入库单在进销存系统录入一遍之后还需要到三方仓储公司系统在录入一遍,两边数据不能同步,重复工作,数据不及时,业务员查不到仓库库存数*三方仓储公司出入库执...

汽车配件仓库如何出库(10分钟做好库存盘点的汽配Excel全自动进销存系统,这份模板收好)

说到汽配行业,sku多也不是一天两天的事了,库存整理难的问题也一直存在,长期以来困扰着我。对配件的库存数心里没底,客户一来问配件,就往仓库跑,配件找半天还找不到,也让我错过了好多单子。好在读书的时候Excel学...

汽车配件出库流程图(仓库盘点六步流程:计划、安排、准备、作业、原因分析和账务处理)

仓库盘点看起来简单,但其实是一个技术活。《盘点是个技术活》系列文章,上一篇,我讲了仓库盘点的分类,本篇,我详细聊聊仓库盘点的流程。 “有事就有流”,管理,需要流程,管理,从某种程度上来说,其实就是流程...

托盘式升降机(探访北京防疫药品“中转站”:药品从入库核验到出库配送,不到4小时)

...来,配送中心的吞吐量比之前增长了六成多。防疫药品从入库到出库,一般控制在4小时内。“药来啦!大家开始核验!”

...系统物料管理系统功能界面设计目的:为了方便物料的出入库管理,方便物料查询、追踪物料出入库记录、以及库存状态及时掌握。物料入库1.1选择物料名称后自动带出相关信息,输入入库数量即可。所有物料均可在下拉框内选...

...系统物料管理系统功能界面设计目的:为了方便物料的出入库管理,方便物料查询、追踪物料出入库记录、以及库存状态及时掌握。物料入库1.1选择物料名称后自动带出相关信息,输入入库数量即可。所有物料均可在下拉框内选...

武汉双软企业认定(出库入库0出错率,仓容量提升50%,纺织车间都在用“神助攻”?)

我国棉纺工厂跟欧美等发达国家相比,自动化水平相对落后;棉纺工厂仍属于典型的劳动密集型企业,需要大量人力,自动化、智能化是今后发展趋势。近年来,随着生活水平的提升,人口老龄化以及劳动人员素质的普遍提高,...

入库、出库分别记录在不同表格里,现在要获取库存。入库、出库的格式一样。库存是一张空白表,要将入库、出库的数据引用过来。进销存大多数公司都会用到,今天,卢子就教你一个通用的处理方法。将入库、出库两个表的...

...理 系统包含各类企业实物资产管理、资产采购管理、入库、出库、借用、归还、转让、报修、盘点等流程。2.耗材管理 系统对耗材出库入库全过程开展管理,对采购生成的入库单开展入