数控铣床编程教学(FANUC系统数控铣床几个简单编程实例)

Posted

篇首语:今天所做之事勿候明天,自己所做之事勿候他人。本文由小常识网(cha138.com)小编为大家整理,主要介绍了数控铣床编程教学(FANUC系统数控铣床几个简单编程实例)相关的知识,希望对你有一定的参考价值。

数控铣床编程教学(FANUC系统数控铣床几个简单编程实例)

FANUC系统数控铣床几个简单编程实例

实例一 平面加工

参考程序:

O0001;

G90 G94 G21 G17;

G91 G28 Z0;

G90 G54 M03 S350;

G00 X-52.0 Y-50.0;

Z5.0 M08;

G01 Z-8.0 F50;

Y50.0 F52;

G00 Z5.0;

X-44.0 Y-50.0;

G01 Z-4.0 F50;

Y50.0 F52;

G00 Z5.0;

X10. Y50.0;

G01 Z-6.0 F50;

G02 X10.0 Y-50.0 R50.0 F52;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

实例二 外形轮廓加工

参考程序:

(1)圆柱台加工程序

O0001;

G90 G94 G40 G17 G21;

G91 G28 Z0;

G90 G54 M3 S350;

G00 X62.0 Y0;

Z5.0;

G01 Z-4.0 F52;

G41 D02 G01 X47.0 Y0 F52;

G02 I-47.0 J0;

G40 G01 X62.0 Y0;

G41 D02 G01 X31.0 YO;

G02 I-31.0 J0;

G40 G01 X62.0 Y0;

G41 D02 G01 X15.0 Y0;

G02 I-15.0 J0;

G40 G01 X62.0 Y0;

G00 Z20.0;

G91 G28 Z0;

M30;

(2)外轮廓加工程序

O0002;

G90 G94 G40 G17 G21;

G91 G28 ZO;

G90 G54 M03 S350;

G00 X-62.0 Y52.0 M08;

Z5.0;

G01 Z-9.0 F52;

G41 D02 G01 X-40.0 Y30.0 F52;

G01 X-20.0 Y30.0;

X30.0;

G02 X40.0 Y20.0 R10.0;

G01 Y-20.0;

G02 X30.0 Y-30.0 R10.0;

G01 X-30.0;

G02 X-40.0 Y-20.0 R10.0;

G01 Y10.0;

G03 X-20.0 Y30.0 R20.0;

G40 G01 X-62.0 Y52.0;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

粗加工时,选用Φ20的立铣刀,刀具号为T02,刀具半径补偿号为D02,补偿值为10.2mm(0.2mm是精加工余量)。

精加工时,选用Φ12的立铣刀,刀具号为T03,刀具半径补偿号为D03,补偿值为6mm。

实例三 槽加工

参考程序:

(1)十字槽粗加工程序

O0001;

G90 G40 G21 G17 G94;

G91 G28 Z0;

G90 G54 M3 S480;

G00 X30.0 Y0;

Z5.0 M08;

G01 Z-4.0 F40;

X-30.0 F60;

Z-8.0 F40;

X30.0 F60;

G00 Z5.0;

X0 Y25.0;

G01 Z-4.0 F40;

Y-25.0;

Z-8.0 F40;

Y25.0 F60;

G00 Z5.0 M09;

G91 G28 Z0;

M30;

(2)十字槽精加工程序

O0002;(主程序)

G90 G40 G21 G94 G17;

G91 G28 Z0;

G90 G54 M3 S800;

G00 X0 Y0;

Z5.0 M08;

G01 Z0 F40;

M98 P0003 L02;

G90 G00 Z5.0 M09;

G91 G28 Z0;

M30;

O0003;(子程序)

G91 G01 Z-4.0 F40;

G90 G41 D03 G01 X12.5 Y7.5 F50;

G02 X7.5 Y12.5 R5.0;

G01 Y25.0;

G03 X-7.5 R7.5;

G01 Y12.5;

G02 X-12.5 Y7.5 R5.0;

G01 X-30.0;

G03 Y-7.5 R7.5;

G01 X-12.5;

G02 X-7.5 Y-12.5 R5.0;

G01 Y-25.0 ;

G03 X7.5 R7.5;

G01 Y-12.5;

G02 X12.5 Y-7.5 R5.0;

G01 X30.0;

G03 Y7.5 R7.5;

G01 X12.5;

G02 X7.5 Y12.5 R5.0;

G40 G01 X0 Y0;

M99;

实例四 型腔加工

参考程序:

(1)型腔内粗加工程序

O0001;(主程序)

G90 G40 G21 G94 G17;

G91 G28 Z0;

G90 G54 M3 S480;

G00 X0 Y0;

Z5.0 M08;

G01 Z0 F50;

M98 P0002 L02;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

O0002;(子程序)

G91 G01 Z-4.0 F40;

G90 G01 X7.0 Y0 F48;

G03 I-7.0 J0;

G01 X19.0 Y0;

G03 I-19.0 J0;

G01 X0 Y0 F100;

M99;

(2)型腔内轮廓精加工程序

O0003;(主程序)

G90 G40 G21 G94 G17;

G91 G28 Z0;

G90 G54 M3 S480;

G00 X5.0 Y0;

Z5.0 M08;

G01 Z0 F80;

M98 P0004 L02;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

O0004;(子程序)

G91 G01 Z-4.0 F80;

G90 G41 D01 G01 X20.0 Y-15.0 F48;

G03 X35.0 Y0 R15.0;

G01 Y6.7157;

G03 X28.3333 Y16.1438 R10.0;

G02 X16.1438 Y28.3333 R20.0;

G03 X6.7157 Y35.0 R10.0;

G01 X-6.7157;

G03 X-16.1438 Y28.3333 R10.0;

GO2 X-28.3333 Y16.1438 R20.0;

G03 X-35.0 Y6.7157 R10.0;

G01 Y-6.7157;

G03 X-28.3333 Y-16.1438 R10.0;

G02 X-16.1438 Y-28.3333 R20.0;

G03 X-6.7157 Y-35.0 R10.0;

G01 X6.7157;

G03 X16.1438 Y-28.3333 R10.0;

G02 X28.3333 Y-16.1438 R20.0;

G03 X35.0 Y-6.7157 R10.0;

G01 Y0;

G03 X20.0 Y15.0 R15.0;

G40 G01 X5.0 Y0;

M99;

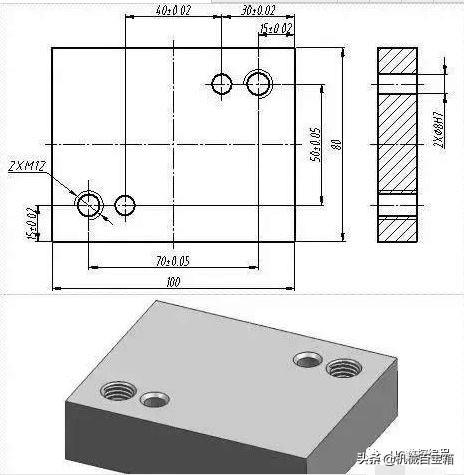

实例五 钻孔、攻丝加工

参考程序:

O0001;

G91 G28 Z0;

M06 T1;

G90 G17 G49 G21 G94;

G54 M3 S1200;

G00 X20.0 Y100.0 M08;

G43 H01 G00 Z50.0;

G99 G81 X-15.0 Y65.0 Z-4.0 R5.0 F80;

G98 X-30.0;

G00 X-120.0;

Y15.0;

G99 G81 X-85.0 Y15.0 Z-4.0 R5.0 F80;

G98 X-70.0;

G91 G28 Z0 M09;

M06 T02;

G90 G49 G54 M3 S550;

G00 X20.0 Y100.0 M08;

G43 H02 G00 Z50. ;

G99 G73 X-15.0 Y65.0 Z-20.0 R5.0 Q2.0 F60;

G98 X-30.0;

G00 X-120.0;

Y15.0;

G99 G73 X-85.0 Y15.0 Z-20.0 R5.0 Q2.0 F60;

G98 X-70.0;

G91 G28 Z0 M09;

M06 T03;

G90 G49 G54 M3 S500;

G00 X20.0 Y100.0 M08;

G43 H03 G00 Z50. ;

G98 G83 X-30.0 Y65.0 Z-21.0 R5.0 Q2.0 F60;

G00 X-120.0;

Y15.0;

G98 G83 X-70.0 Y15.0 Z-21.0 R5.0 Q2.0 F60;

G91 G28 Z0 M09;

M06 T04;

G90 G49 G54 M3 S450;

G00 X20.0 Y100.0 M08;

G43 H04 G00 Z50. ;

G98 G81 X-15.0 Y65.0 Z-21.0 R5.0 F50;

G00 X-120.0;

Y15.0;

G98 G81 X-85.0 Y15.0 Z-21.0 R5.0 F50;

G91 G28 Z0 M09;

M06 T05;

G90 G49 G54 M3 S350;

G00 X20.0 Y100.0 M08;

G43 H05 G00 Z50.0;

G99 G82 X-15.0 Y65.0 Z-6.0 R5.0 P2000 F60;

G98 X-30.0;

G00 X-120.0;

Y15.0;

G99 G82 X-85.0 Y15.0 Z-6.0 R5.0 P2000 F60;

G98 X-70.0;

G91 G28 Z0 M09;

M06 T06;

G90 G49 G54 M3 S50;

G00 X20.0 Y100.0 M08;

G43 H06 G00 Z50.0;

G98 G85 X-30.0 Y65.0 Z-18.0 R5.0 F40;

G00 X-120.0;

Y15.0;

G98 G85 X-70.0 Y15.0 Z-18.0 R5.0 F40;

G91 G28 Z0 M09;

M06 T07;

G90 G49 G54 M3 S100;

G00 X20.0 Y100.0 M08;

G43 H07 G00 Z50.0;

G98 G84 X-15.0 Y65.0 Z-19.0 R5.0 F175;

G00 X-120.0;

Y15.0;

G98 G84 X-85.0 Y15.0 Z-19.0 R5.0 F175;

G91 G28 Z0 M09;

M30;

实例六 镗孔加工

参考程序:

O0001;

G91 G28 Z0;

M06 TO1;

G90 G94 G49 G17 G40 G21;

G54 M03 S400;

G43 H01 G00 Z50.0 M08;

X-46.0 Y55.0;

Z5.0;

G01 Z-4.0 F80;

Y-55.0 F60;

X46.0 F1000;

Y55.0 F60;

G41 D01 G01 X17.321 Y30.0 F60;

X34.641 Y0;

X17.321 Y-30.0;

X-17.321;

X-34.641 Y0;

X-17.321 Y30.0 ;

X-20.0;

G40 G01 X65.0 Y55.0 F300;

G91 G28 Z0 M09;

M06 T03;

G90 G54 G49 G40 M03 S1200;

G43 H03 G00 Z50.0 M08;

G98 G81 X0 Y0 Z-4.0 R5.0 F60;

G91 G28 Z0 M09;

M06 T04;

G90 G54 G49 G40 M03 S500;

G43 H04 G00 Z50.0 M08;

G98 G81 X0 Y0 Z-20.0 R5.0 F60;

G91 G28 Z0 M09;

G28 X0 Y0;

M06 T05;

G90 G54 G49 G40 M03 S350;

G43 H05 G00 Z50.0 M08;

G98 G73 X0 Y0 Z-22.0 R5.0 Q2.0 F50;

G91 G28 Z0 M09;

G28 X0 Y0;

M06 T06;

G90 G54 G49 G40 M03 S250;

G43 H06 G00 Z50.0 M08;

G98 G73 X0 Y0 Z-25.0 R5.0 Q2.0 F45;

G91 G28 Z0 M09;

G28 X0 Y0;

M06 T07;

G90 G54 G49 G40 M03 S200;

G43 H07 G00 Z50.0 M08;

G98 G73 X0 Y0 Z-26.0 R5.0 Q2.0 F40;

G91 G28 Z0 M09;

M06 T02;

G90 G54 G49 G40 M03 S800;

G43 H02 G00 Z50.0 M08;

X46.0 Y55.0;

Z5.0;

G01 Z-4.0 F80;

G41 D02 G01 X17.321 Y30.0 F60;

X34.641 Y0;

X17.321 Y-30.0;

X-17.321;

X-34.641 Y0;

X-17.321 Y30.0;

X-20.0;

G40 G01 X65.0 Y55.0 F300;

G91 G28 Z0 M09;

M06 T08;

G90 G54 G49 G40 M03 S800;

G43 H08 G00 Z60.0 M08;

G98 G85 X0 Y0 Z-17.0 R5.0 F60;

G91 G28 Z0 M09;

M06 T09;

G90 G54 G49 G40 M03 S1500;

G43 H09 G00 Z60.0 M08;

G98 G85 X0 Y0 Z-17.0 R5.0 F50;

G91 G28 Z0 M09;

G28 X0 Y0;

M30;

实例七 镜像加工

参考程序:

O0001;(主程序)

G90 G40 G21 G17 G94;

G50.1 X0 Y0;

G91 G28 Z0;

G90 G54 M3 S680;

M08;

M98 P0002;

G51.1 X0;

M98 P0002;

G50.1 X0;

M09;

M30;

O0002;(子程序)

G00 X-58.0 Y-48.0;

Z50.0;

Z5.0;

G01 Z-3.0 F50;

G41 D01 G01 X-47.0 Y-45.0 F100;

X-47.0 Y-20.0;

X-37.0 Y-20.0;

G03 X-27.0 Y-10.0 R10.0;

G01 X-27.0 Y10.0;

G03 X-37.0 Y20.0 R10.0;

G01 X-47.0 Y20.0;

X-47.0 Y42.5;

X-28.0 Y42.5;

G02 X-8.0 Y22.5 R20.0;

G01 X-8.0 Y-20.0;

X-30.5 Y-42.5;

X-50.0 Y-42.5;

G40 G01 X-58.0 Y-48.0;

G00 Z50.0;

M99;

实例八 极坐标加工

参考程序:

O0001;

G54 G40;

M08;

G15;

M03 S700;

G00 X58.0 Y-10.0;

Z50.0;

Z5.0;

G01 Z-5.0 F50;

G41 D01 G16 G01 X36.0 Y-5.0 F100;

G02 X24.0 Y-5.0 R6.;

G03 X24.0 Y275.0 R-24.0;

G02 X36.0 Y275.0 R6.0;

G02 X36.0 Y-5.0 R-36.0;

G40 G15 G01 X58.0 Y-10.0;

G00 Z150.0;

M09;

M30;

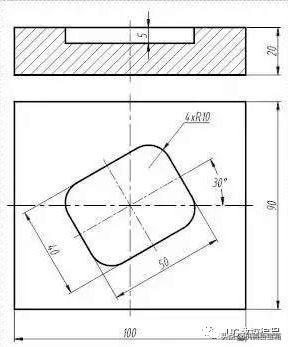

实例九 旋转加工

参考程序:

O0001;

G54 G40;

G69;

M03 S700;

G68 X0 Y0 R30.0;

G00 X0 Y0;

Z50.0 M08;

Z5.0;

G01 Z-5.0 F50;

G41 D01 G01 X25.0 Y10.0 F100;

G03 X15.0 Y20.0 R10.0;

G01 X-15.0;

G03 X-25.0 Y10.0 R10.0;

G01 Y-10.0;

G03 X-15.0 Y-20.0 R10.0;

G01 X15.0;

G03 X25.0 Y-10.0 R10.0;

G01 X25.0 Y10.0;

G40 G01 X0 Y0;

G00 Z150.0 M09;

M30;

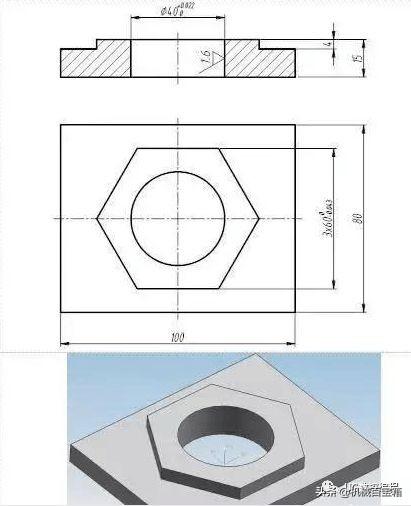

实例十 综合零件加工

参考程序:

(1)正六边形加工程序

O0001;

G90 G40 G21 G17 G94;

G91 G28 Z0;

G90 G54 M03 S400;

G00 X0 Y55.0;

Z5.0 M08;

G01 Z-6. F60;

G41 D01 G01 X0 Y29.0 F100;

X10.97;

G02 X19.63 Y24.0 R10.0;

G01 X30.60 Y5.0;

G02 Y-5.0 R10.0;

G01 X19.63 Y-24.0;

G02 X10.97 Y-29.0 R10.0;

G01 X-10.97;

G02 X-19.63 Y-24.0 R10.0;

G01 X-30.60 Y-5.0;

G02 Y5.0 R10.0;

G01 X-19.63 Y24.0;

G02 X-10.97 Y29.0 R10.0;

G01 X0;

G40 G01 X0 Y55.0;

G00 Z50.0 M09;

G91 G28 Z0;

M30;

(2)斜六边形加工主程序

O0002;(主程序)

G90 G40 G21 G17 G94 G69;

G91 G28 Z0;

G90 G68 X0 Y0 R10.0;

M98 P0003;

G69;

G91 G28 Z0;

M30;

O0003;(子程序)

G90 G54 M03 S400;

G00 X0 Y40.0;

Z5.0 M08;

G01 Z-4. F60;

G41 D01 G01 X0 Y25.0 F100;

X10.97;

G02 X16.17 Y22.0 R6.0;

G01 X27.14 Y3.0;

G02 Y-3.0 R6.0;

G01 X16.17 Y-22.0;

G02 X10.97 Y-25.0 R6.0;

G01 X-10.97;

G02 X-16.17 Y-22.0 R6.0;

G01 X-27.14 Y-3.0;

G02 Y3.0 R6.0;

G01 X-16.17 Y22.0;

G02 X-10.97 Y25.0 R6.0;

G01 X0;

G40 G01 X0 Y40.0;

G00 Z50.0 M09;

M99;

(3)凹槽加工程序

O0004;(主程序)

G90 G40 G21 G17 G94;

G54 M03 S680;

GO0 X60 Y-50;

Z5.0 M08;

M98 P0005;

G51.1 X0 Y0 ;

M98 P0005;

G50.1 X0 Y0 ;

G0 Z100.0 M09;

M30

O0005;(子程序)

G00 X56.0 Y-46.0;

G01 Z-8.0 F50;

G41 D04 G01 X52.34 Y-33.55 F ;

X34.88 Y-19.58;

G3 X26.76 Y-29.73 R6.5;

G1 X41.94 Y-41.87;

G40 G01 X56.0 Y-46.0;

G00 Z5.0;

M99;

(4)孔加工程序

O0006;

G91 G28 Z0;

M06 T05;

G90 G40 G21 G17 G94 G15;

G54 M03 S1500;

GO0 X0 Y0;

G43 H05 G00 Z20.0;

G16 G00 X40.0 Y40.0;

G99 G81 Z-9.0 R5.0 F60;

G00 X40.0 Y210.0;

G98 G81 Z-9.0 R5.0 F60;

G15;

G91 G28 Z0;

M06 T06;

G90 G15 G54 M3 S500;

GO0 X0 Y0;

G43 H06 G00 Z20.0;

G16 G00 X40.0 Y40.0;

G99 G81 Z-20.0 R5.0 F60;

G00 X40.0 Y210.0;

G98 G81 Z-20.0 R5.0 F60;

G15;

G91 G28 Z0;

M06 T07;

G90 G15 G54 M03 S450;

GO0 X0 Y0;

G43 H07 G00 Z20.0;

G16 G00 X40.0 Y40.0;

G99 G81 Z-20.0 R5.0 F50;

G00 X40.0 Y210.0;

G98 G81 Z-20.0 R5.0 F50;

G15;

G91 G28 Z0;

M06 T08;

G90 G15 G54 M03 S500;

GO0 X0 Y0;

G43 H08 G00 Z20;

G16 G00 X40.0 Y40.0;

G99 G82 Z-10.0 R5.0 P2000 F60;

G00 X40.0 Y210.0;

G99 G82 Z-10.0 R5.0 P2000 F60;

G15;

G91 G28 Z0;

M06 T09;

G90 G15 G54 M03 S50;

GO0 X0 Y0;

G43 H09 G00 Z20.0;

G16 G00 X40.0 Y40.0;

G99 G85 Z-18.0 R5.0 F40;

G00 X40.0 Y210.0

G98 G85 Z-18.0 R5.0 F40;

G15;

G91 G28 Z0;

M30;

相关参考

数控车床30度倒角怎么编程(针对FANUC数控系统任意倒角指令的讲解,分享个人一点经验)

...参考程序如下:...G01X24Z0X30Z-3Z-20X46.54X50Z-23Z-40....为了提高编程的效率和精确度,数控系统提供了倒角指令,简单说:倒直角、倒圆角和任

主轴转速1000Vc(切削速度)m/min∏(3.14)Dc(铣刀公称直径)mmn(主轴转速)rev/min1000303.1410955.4140127工作台进给量fz(每齿进给量)n(主轴转速)rev/minZn(刃数)Vf(工作台进给量)进给速度mm/min0.02560002300每齿进给量Vf每分钟工作台进给速度...

数控系统属于什么(数控车加工一本就够FANUC和SIEMENS两大主流系统对比讲解)

...操作系统)、数控刀具、夹具(工件的装夹);其次考虑编程零点的设置、编程时的数据处理、数据点的计算;然后编制程序,编程时还要考虑程序简单易行,机床便于操作。数控加工主要依据数控加工工艺和加工程序要求来完...

数控及CNC加工(数控车加工一本就够FANUC和SIEMENS两大主流系统对比讲解)

...操作系统)、数控刀具、夹具(工件的装夹);其次考虑编程零点的设置、编程时的数据处理、数据点的计算;然后编制程序,编程时还要考虑程序简单易行,机床便于操作。数控加工主要依据数控加工工艺和加工程序要求来完...

数控自动车床编程(FANUC 0i系统数控车床的编程与操作一一请收藏)

大家好,我是ug编程美丽老师,今天分享FANUC0i系统数控车床的编程与操作(干货知识),很详细,重点是每个功能讲的明明白白,每天进步一点点,未来可期。如果你需要,可以一起分享学习。找到我的,百分百会发。领取途径...

数控机床主要由什么组成(数控车加工一本就够FANUC和SIEMENS两大主流系统对比讲解)

...操作系统)、数控刀具、夹具(工件的装夹);其次考虑编程零点的设置、编程时的数据处理、数据点的计算;然后编制程序,编程时还要考虑程序简单易行,机床便于操作。数控加工主要依据数控加工工艺和加工程序要求来完...

数控机床的基本组成包括哪些(数控车加工一本就够FANUC和SIEMENS两大主流系统对比讲解)

...操作系统)、数控刀具、夹具(工件的装夹);其次考虑编程零点的设置、编程时的数据处理、数据点的计算;然后编制程序,编程时还要考虑程序简单易行,机床便于操作。数控加工主要依据数控加工工艺和加工程序要求来完...

数控G03圆球头编程实例(第三章 FANUC oi系统数控车床操作)

第一节FANUCO-TDⅡ控制面板一、系统功能指令表在表3-1中列出的是FANUCO-TDⅡ系统常用指令。表3-1系统功能指令表G(M)代码组功能*G00G01G02G0301组定位(快速进给)直线插补(切削进给)圆弧插补CW(顺时针)圆弧插外CCW(逆时针)G0...

法兰克数控车床攻丝程序(FANUC系统极坐标G16指令用法)

...几乎很常见。那么怎么用G16指令进行加工呢?因为其指令编程简单。修改方便。所以很多做加工中心朋友都会用。这里再讲一下具体用法,会的朋友感谢您的阅读,不会的朋友可以借鉴编程方法。如图:钻四个圆周等分孔。从图...

法兰克数控车床攻丝程序(FANUC系统极坐标G16指令用法)

...几乎很常见。那么怎么用G16指令进行加工呢?因为其指令编程简单。修改方便。所以很多做加工中心朋友都会用。这里再讲一下具体用法,会的朋友感谢您的阅读,不会的朋友可以借鉴编程方法。如图:钻四个圆周等分孔。从图...