数控车床加工内孔R角怎么编程(数控车床编程实例)

Posted

篇首语:学者之所以是学者,不是因为他博学,而是因为他一直保有求知欲。本文由小常识网(cha138.com)小编为大家整理,主要介绍了数控车床加工内孔R角怎么编程(数控车床编程实例)相关的知识,希望对你有一定的参考价值。

数控车床加工内孔R角怎么编程(数控车床编程实例)

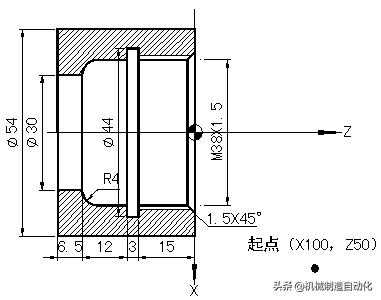

例一.图示如下零件

材料:黄铜, 毛坯:锻件, 单边余量约1mm,

螺纹为公制直螺纹,螺距1.5mm

1#刀:内孔刀; 2#刀:割槽刀(刀宽为槽宽3mm); 3#刀:螺纹刀

刀具起始点为(X100,Z50);

N0010 M03 S1500

N0020 G00 X100 Z50

N0030 T1

N0040 G00 X30

N0050 G00 Z0

N0060 G01 X55 F150 (加工端面)

N0070 G01 X39.5

N0080 G01 X36.5 Z-1.5 (倒角1.5×45)

N0090 G01 Z-26 (车削内孔φ38)

N0100 G03 X30 Z-30 R4 F100 (车削内圆弧R4)

N0110 G01 Z-37 (车削内孔φ30)

N0120 G00 X28 (X向退刀)

N0130 G00 Z50 (Z向退刀)

N0140 T2 (换内孔刀割槽)

N0150 G00 X35 (快速进刀)

N0160 G00 Z-18 (快速进刀)

N0170 G01 X44 F150 (割槽)

N0180 G00 X36 (快速退刀)

N0190 G00 Z50 (快速退刀)

N0200 T3 (换螺纹刀加工螺纹)

N0210 S700

N0220 G00 X36.5 Z2 (快速进刀)

N0230 G86 Z-16 K1.5 I-4 R2 L4 (加工螺纹)

N0240 G00 X100 Z80

N0250 M05

N0260 T1

N0270 G00 X100 Z50

N0280 M02

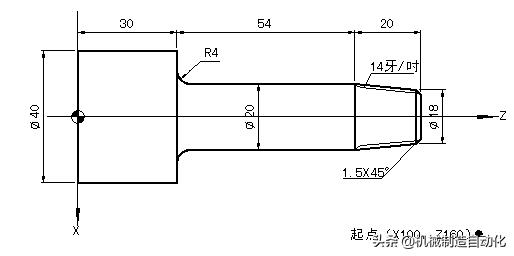

例二.图示如下零件

材料:45#, 毛坯:锻件, 单边余量约1mm,

螺纹为英制锥螺纹,螺距每英寸14牙,

1#刀:外圆刀, 2#刀:外螺纹刀

刀具起始点为(X100,Z160)

N0010 M03 S1000

N0020 M08

N0030 G00 X100 Z160

N0040 T1

N0050 G00 X44 Z30.2 (快速进刀)

N0060 G01 X30 F120 (粗车端面)

N0070 G00 Z107 (快速退刀)

N0080 G00 X18.4 (快速进刀)

N0090 G01 Z104 F120 (慢速进刀)

N0100 G01 X20.4 Z84 (粗车外锥, 直径余量0.4)

N0110 G01 Z34 (粗车外圆φ20)

N0120 G02 X28 Z30.2 R3.8 F80 (粗车R4)

N0130 G01 X40.2 F120 (粗车端面)

N0140 G01 Z10 (粗车外圆φ40)

N0150 G00 Z104 (快速退刀)

N0160 S1500

N0170 G00 X24 (快速进刀)

N0180 G01 X10 F120 (精车端面)

N0190 G01 X15

N0200 G01 X18 Z102.5 (倒角1.5×45)

N0210 G01 X20 Z84 (精车锥度)

N0220 G01 Z34 (精车外圆φ20)

N0230 G02 X28 Z30 R4 F80 (精车R4)

N0240 G01 X40 F120 (精车端面)

N0250 G01 Z10 (精车外圆φ40)

N0260 G00 X100 Z160 (快速退刀)

N0270 T2 (换螺纹刀加工螺纹)

N0280 S700

N0290 G00 X17.8 Z106 (快速进刀)

N0300 G87 X20 Z84 K14 I4 R1.96 L8 (车削锥度螺纹)

N0310 G00 X100 Z160

N0320 M05

N0330 M09

N0340 T1

N0350 G00 X100 Z160

N0360 M02

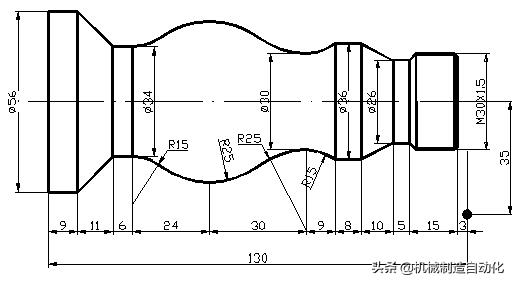

例三.下图所示零件,共用三把刀具,

1#刀:为90°外圆刀,2#刀:5mm切槽刀(5mm),3#刀:60°螺纹刀

毛坯尺寸φ60χ150,材料:铝。

编程如下:

N0010 G00 X70 Z130

N0020 M03 S800

N0030 G01 Z127 F80 (慢速进刀)

N0040 X-0.5 (车端面)

N0050 G00 Z130 (快速退刀)

N0060 X56.2 (快速退刀)

N0070 G01 Z0 F80 (粗车外圆φ56)

N0080 G0 X58 (快速退刀)

N0090 Z130 (快速退刀)

N0100 G01 X50.5 F80 (慢速进刀)

N0110 Z14 (粗车外圆)

N0120 G00 X52 (快速退刀)

N0130 Z130 (快速退刀)

N0140 G01 X44 F80 (慢速进刀)

N0150 Z70 (粗车外圆)

N0160 G00 X46 (快速退刀)

N0170 Z130 (快速退刀)

N0180 G01 X40 F80 (慢速进刀)

N0190 Z70 (粗车外圆)

N0200 G00 X42 (快速退刀)

N0210 Z130 (快速退刀)

N0220 G01 X36.2 F80 (慢速进刀)

N0230 Z75 (粗车外圆)

N0240 G00 X38 (快速退刀)

N0250 Z130 (快速退刀)

N0260 G01 X28.5 F80 (慢速进刀)

N0270 X30.5 Z125 (倒角)

N0280 Z104 (粗车外圆)

N0290 G00 X90 (快速退刀)

N0300 Z200 (快速退刀)

N0310 T02

N0320 M03 S400

N0330 G00 Z107 (快速进刀)

N0340 X32 (快速进刀)

N0350 G01 X26.2 F20

N0360 G00 X52 (快速退刀)

N0370 Z20 (快速退刀)

N0380 G01 X34.2 F20 (粗车外圆)

N0390 G01 X52 F80 (慢速退刀)

N0400 G00 Z200 (快速退刀)

N0410 T3 S1200

N0420 G00 X32 Z127

N0430 G01 X30 F80 (慢速进刀)

N0440 Z114 (精车螺纹外圆φ30)

N0450 X26 Z112 (倒角)

N0460 Z107 (精车外圆φ26)

N0470 X36 Z97 (精车锥度)

N0480 Z89 (精车外圆φ36)

N0490 X54 Z50 (粗车外圆)

N0500 X38 Z26 (粗车外圆)

N0510 Z20 (粗车外圆)

N0520 X58 Z9

N0530 G00 Z97 (快速退刀)

N0540 G01 X36 F80 (慢速进刀)

N0550 Z89 (慢速进刀)

N0560 G02 X30 Z80 R15 (精车顺圆弧R15)

N0570 G02 X40 Z65 R25 (精车顺圆弧R25)

N0580 G03 X40 Z35 R25 (精车逆圆弧R25)

N0590 G02 X34 Z26 R15 (精车顺圆弧R15)

N0600 G01 Z20 (精车外圆φ34)

N0610 X56 Z9 (精车锥度)

N0620 Z0 (精车外圆φ56)

N0630 S400

N0640 G00 X58 (快速退刀)

N0650 Z132 (快速退刀)

N0660 X30 (快速进刀)

N0670 G86 Z110 K1.5 I4 R1.35 L8 (车削螺纹)

N0680 G0 X70 (快速退刀)

N0690 Z200 (快速退刀)

N0700 T1

N0720 M02

相关参考

本期开始,咱们来看看数控车编程实例!欢迎大家参与讨论!例:编制图1所示零件的加工程序。工艺条件:工件材质为45#钢,或铝;毛坯为直径Φ54mm,长200mm的棒料;刀具选用:1号端面刀加工工件端面,2号端面外圆刀粗加工工...

例1.G01直线插补指令编程如下图所示安装装仿形工件请设置安装装仿形工件,各点坐标参考如下(X向余量4mm)FANUC数控车编程如下:O9001N10G50X100Z10(设立坐标系,定义对刀点的位置)N20G00X16Z2M03(移到倒角延长线,Z轴2mm处)N30G01U10W-5G...

直线插补指令G01数控编程直线插补指令G01数控编程零件图样%3305N1G92X100Z10(设立加工工件坐标系,定义对刀点的位置)N2G00X16Z2M03(移到倒角延长线,Z轴2mm处)N3G01U10W-5F300(倒3×45°角)N4Z-48(加工Φ26外圆)N5U34W-10(切第一段锥)...

数控车床内圆R角怎么编(数控车上加工圆弧螺纹宏程序,这个案例值得你学习)

运用宏程序编程优点还很多,比如说刀具寿命管理,安全预测程序开发,数控G指令开发,产品、磨具参数化编程等等。学会宏程序编程是一件多么夸姣的事啊!说起大螺距圆弧螺纹加工,批量生产大多用旋风铣来加工可是一些...

数控车床编程实例(120页数控车床程序的编制及操作,数控车床编程,车削加工实例)

这是一本学习的书,也是一本练习的册子,它把内容分为数控车床加工技能实训、数控铣床加工技能实训和数控车铣综合加工技能实训三个学习情境,每个学习情境又根据相应岗位职业能力需求,划分为数控机床操作基础模块、...

数控G03圆球头编程实例(第三章 FANUC oi系统数控车床操作)

第一节FANUCO-TDⅡ控制面板一、系统功能指令表在表3-1中列出的是FANUCO-TDⅡ系统常用指令。表3-1系统功能指令表G(M)代码组功能*G00G01G02G0301组定位(快速进给)直线插补(切削进给)圆弧插补CW(顺时针)圆弧插外CCW(逆时针)G0...

数控车床上用钻头打孔编程(数控加工中心简单的钻孔手工编程实例讲解)

之前发表过一篇关于数控加工中心的文章,有数控朋友指出,有例子没有图解,还是不会。今天就给大家补充一点,举两个关于钻孔手工编程的例子。关于手工编程,我已经谈过,无需深入了解,只要会编点简单的钻,铣孔及铣...

实例一:毛坯为70㎜×70㎜×18㎜板材,六面已粗加工过,要求数控铣出如图3-23所示的槽,工件资料为45钢。1.依据图样要求、毛坯及前道工序加工状况,确认工艺方案及加工道路1)以已加工过的底面为定位基准,用通用台虎钳夹...

数控车床g98编程实例(FANUC数控铣床编程实例18-复杂凹十字台加工)

下图零件是在方形零件上方加工六棱凸台,再在凸台上加工二层凹槽。可以使用φ13立铣刀加工这些特征,另外的三个孔可以使用钻头和铰刀加工。工步1:铣削棱柱凸台走刀轨迹如下参考程序T3M6G90G54G40G43H3G00Z100M03S2500M08G00X70Y23G00Z...