微电脑全吸料机(上料机,吸料机,提升机的区别及用途)

Posted

篇首语:不操千曲而后晓声,观千剑而后识器。本文由小常识网(cha138.com)小编为大家整理,主要介绍了微电脑全吸料机(上料机,吸料机,提升机的区别及用途)相关的知识,希望对你有一定的参考价值。

微电脑全吸料机(上料机,吸料机,提升机的区别及用途)

螺杆上料机

特点

ASL系列螺旋上料机专为塑料及粉体生产加工行业设计制造

本机与物料接触部分全部采用不锈钢制作,可与各种规格挤出机、高速混合机、塑料搅拌机配套使用,广泛适用于各类粉状、粒状、回料破碎等物料的上(送)料用途

本系列机型单机上料高度可达2-6料,并可多机串联使用,抽送上料速度为1-3吨/每小时。具有:自动控制加料,维修方便,安全可靠,提高工作效率等优点

Screw feeder

Features

The ASL series of screw feeders are designed and manufactured for the plastics and powders processing industry , The contact part of the machine and the material are all made of stainless steel , it can be used with extruders of various specifications , high-speed mixers and plastic mixers ; it is widely used in all kinds of powder , granular and recycled materials . (send ) material use

The height of the single machine of this series can reach 2-6 meters , it can be used in series with multiple machines , and the feeding speed is 1-3 tons / hour . it has the advantages of automatic control feeding , convenient maintenance , safety and reliability , and improved work efficiency

真空吸料(粉)机

特点

微电脑操作控制程序,过载,缺料报警

300G采用高速整流马达,噪音小,寿命长

主机与料斗一体式设计,体积小,重量轻

700G采用高速整流马达,体积小,吸料强,适合用于新料输送

400G、800G、900G及大功率吸料机采用感应式高压风机,噪音小,寿命长

800G具有逆转自动清除粉尘功能

主机与料斗分体设计,安全,简便,独立滤清装置,方便清除粉尘

Vacuum Suction (powder ) Machine

Features

Microprocessor programmed operation , overload , material shortage alarm

300G adopted high-speed motor , small noise , long service life

The host and the hopper integrated design , small volume , light weight

700G adopted high-speed motor , small volume , suction is strong , suitable for new material conveying

800G , 900G using induction type high pressure fan , low noise ,long life

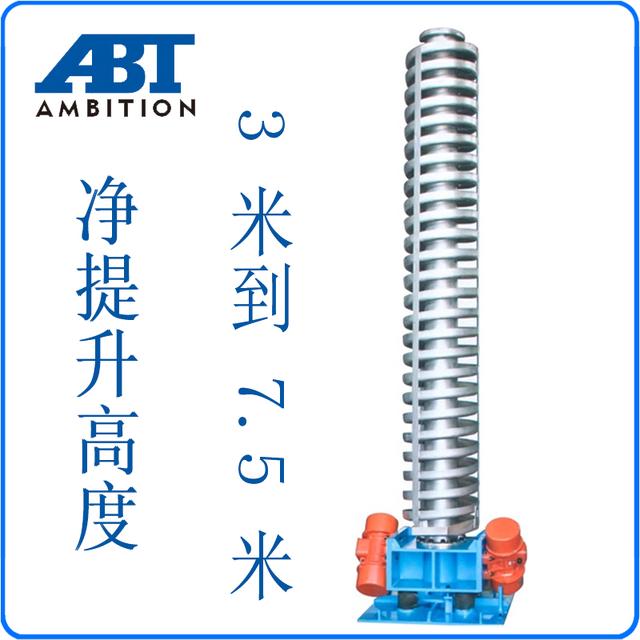

螺旋振动垂直提升机

螺旋振动提升机采用当今最先进的结构设计及模具成型工艺,针对冷却降温干燥和无损输送场合而开发的特定设备,广泛应用于塑料、化工、食品、矿业等加工行业多种物料形态的冷却,干燥和提升输送,在塑料及化工行业我们具有近50套各类型振动提升机工程应用,具备大、中、小全系列提升机量产化制造经验,并打破了大型振动提升机被进口设备垄断的历史

Spiral Vibration Vertical Hoist

Spiral vibrating conveyor adopts state-to-art structural design and molding process , it is specific equipment , developed for cooling , drying and nondestructive conveying way , it is widely used in processing industries such as plastic , chemistry , food and mining industry , etc for cooling ,drying and lifting and conveying of materials in multiple forms In plastic and chemical industries , we have obtained approximately 50 sets of various kinds of spiral vibrating conveyor engineering applications , had experience in mass manufacturing of small , intermediate and Barge full series of vibrating conveyor and broken the history for large-scale vibrating conveyor to be monopolized by imported equipment

特点

一机多用,同时满足垂直输送和降温干燥

结构紧凑,占地面积小

可按客户生产需求定制,最高提升高度8米,最大输送量4T/H

品牌振动电机,满足长时间连续化生产,工作稳定,维护简便

振动盘为2-4MM厚304不锈钢,采用大型模具一次成型工艺,外圈与内圈各自经拉伸形成螺旋挡板及加强筋板,再与不锈钢中心管连续无应力焊接,最大程度上克服了振动产生的扭曲应力和金属疲劳开裂,整体结构强度完全达到德制设备标准

振动盘螺旋均匀,无发拱翘曲现象,物料以排队形式沿螺旋匀速平稳向上输送,在任何高度均无明显回流现象(与第一代提升机显著区别)

输送槽内部圆滑无死角积料,便于不同产品的切换清理,交叉污染风险大大降低

通过振动结构最优化设计,最大程度实现惯性振动,噪音低于80分贝,相对第一代提升机,电耗降低30-50%

中心立柱支撑结构,更稳固安全

停车制动设计,可在2秒内完全停止振动,避免停车共振破坏

进料和出料采用加厚及加固设计,提高使用寿命

可按客户要求设计变频控制,按实际要求调节输送时间和速度

可按客户要求设计风冷,提高冷却效率

可按客户要求增加振动盘夹套结构,通冷却介质以强化冷却

Features

A machine serves several purposes , and meanwhile it satisfies vertical conveying cooling and drying

Structure is compact , with small space required

It can be customized according to production requirements of customer , maximum lifting height is 8m and maximum conveying capacity is 4t/h

Brand vibrating motor can meet long-time continuous production with stabile operation and easy maintenance , Vibration disc , is made of 2-4 mm thick 304 stainless steel , adopting one – time forming process of large –scale mould

The outer ring and the inner ring is formed to be . spiral baffle plate and reinforcement plats separately by tension . Discs are continuously welded with stainless steel central tube without stress , which can overcome the torsional stress and metal fatigue crack generated by vibration so that the overall structure strength fully meets the standard of equipment manufactured in germany

Vibration disc screws are uniform without warping , Materials is transported upward in line along the spiral at uniform and smooth speed and has no back-flow at any height . (it is the significant difference from the first generation type )

Inside the conveying groove is smooth without dead angle for accumulated materials Convenient for switching to clean different products and greatly reduces cross contamination risks

Through optimization design of vibration structure it maximizes to realize inertial vibration with noise reduced to 80 dB and power consumption is reduced by 30-50% , compared with the first generation type

With central pillar support structure , it is more stable and safe

With shut-down brake design , it can stop vibration within 2 seconds , avoiding resonance damage when shut-down

It adopts thickening and reinforcement design for inlet and outlet so as to improve service life

It can be designed for frequency convertor control according to customer requirements , and adjust conveying time and speed

It can be designed for additional air cooling according to customer requirements , and improve cooling efficiency

Additional cooling channel disk design is optional

工作原理

利用对称振动电机产生斜向高频振动力偶,使物料以振动形式沿转盘螺旋形向上爬升,高温物料在长距离输送过程中得以充分传热和散热

Working Principle

It utilizes symmetric vibrating motor to produce oblique high frequency vibration couple so as to make material spiral upward along turntable in vibration mode , high temperature material can get sufficient heat transmission and heat dissipation during long distance transport process

特点

代替传统风送或气相输送系统,更易于清理,无易损部件

能耗明显降低,节电节气

物料冷却均匀彻底,无内热积聚效应,避免因长时间高温导至变色和降解,产品品质明显改善

充分利用自身散热干燥颗粒表面水分,不经过额外干燥即可满足客户常规注塑要求,提高产品附加值

Features

Replace traditional pneumatic conveying pipeline or dense phase conveying system , it can be more easy to clean without easily wearing parts

It can reduce energy consumption obviously and save electricity and gas

Material is cooled uniformly and thoroughly , avoiding discoloration and degradation caused by tong-time high temperature , and product quality is improved obviously

Make fuji use of self –heat dissipation to dry moisture on granule surface . Without additional drying ,it can satisfy , the conventional injection molding requirements and increase the added value of the products

相关参考

注塑机自动吸料机原理(真空上料机-替代传统物料输送模式-河南圆振机械)

真空上料机-取代传统物料传输模式真空上料机,是利用真空负压原理,把物料从吸料口吸进料仓,再通过料仓内的开关阀门控制物料的出料时间,全程工作密闭,可由智能电脑控制,符合环保生产要求的同时大大减少了人力投...

微电脑自动吸料机(什么是计量混色设备?有哪些特点?华热机械:计量混色系列介绍)

宁波华热机械制造有限公司公司成立于1998年,是一家集设计、制造、销售为一体的橡塑辅机高新技术企业,也是国内最早开发塑料加工辅助设备的厂家之一,华热机械配有各类先进专业的制造检测设备,是橡塑辅机行业国内品...

由聚优榜主办的“2022年度吸料机行业十大品牌”评选活动完美落下帷幕。本次活动旨在推出吸料机行业企业信誉好、品牌美誉度高、产品质量优的行业十大品牌。成功入围2022年度吸料机行业十大品牌的企业有:第一名:新乡市...

欧式除尘吸料机(吸料天车全方面讲解。产品介绍、哪几部分组成、操作流程等)

关于吸料天车的一个深入的介绍,就拿科特尔吸料天车来举例说明。今天的内容有:1.吸料天车是什么样的环保系列设备。(这一部分就是所谓的“什么是吸料天车”)2.吸料天车的六大组成部分,包括组成部分都是作用在吸料...

注塑机自动吸料机维修(注塑产品表面有流痕的故障分析及改善方法)

名词解释 成型制品表面的线状痕迹,此痕迹显示了熔料流动的方向。故障分析及排除方法 1、熔料流动不良导致塑件表面产生以浇口为中心的年轮状波流痕。可分别采取提高模具及喷嘴温度,提高注射速率和充模速度,增加注射...

注塑机自动吸料机维修(注塑产品表面有流痕的故障分析及改善方法)

名词解释 成型制品表面的线状痕迹,此痕迹显示了熔料流动的方向。故障分析及排除方法 1、熔料流动不良导致塑件表面产生以浇口为中心的年轮状波流痕。可分别采取提高模具及喷嘴温度,提高注射速率和充模速度,增加注射...

注塑吸料机常见故障(注塑件成型缺陷分析:如何控制注塑产品的色差)

色差是注塑中常见的缺陷,因配套件颜色差别造成注塑机成批报废的情况并不小见。色差影响因素众多,涉及原料树脂、色母(或色粉)、色母同原料的混合、注塑工艺、注塑机、模具等,正因为牵涉面广泛,因此色差控制技术...

注塑吸料机常见故障(注塑件成型缺陷分析:如何控制注塑产品的色差)

色差是注塑中常见的缺陷,因配套件颜色差别造成注塑机成批报废的情况并不小见。色差影响因素众多,涉及原料树脂、色母(或色粉)、色母同原料的混合、注塑工艺、注塑机、模具等,正因为牵涉面广泛,因此色差控制技术...

济南吸料机(财鑫闻丨“一盔一带”新规让头盔概念股应声大涨,全国六千头盔企业或迎风口)

大众网·海报新闻济南5月19日讯(记者沈童)相信昨晚很多人的朋友圈都被“头盔”刷屏了。据公安部消息,为进一步提升摩托车、电动自行车骑乘人员和汽车驾乘人员安全防护水平,有效减少交通事故死亡人数,近日,公安部...

济南吸料机(财鑫闻丨“一盔一带”新规让头盔概念股应声大涨,全国六千头盔企业或迎风口)

大众网·海报新闻济南5月19日讯(记者沈童)相信昨晚很多人的朋友圈都被“头盔”刷屏了。据公安部消息,为进一步提升摩托车、电动自行车骑乘人员和汽车驾乘人员安全防护水平,有效减少交通事故死亡人数,近日,公安部...